Eddy Current Testing Resources, Training, and Equipment

EddyCurrent.com is the industry’s one-stop resource for all things related to eddy current testing. Whether you’re a technician, engineer, researcher, or training provider, this site offers curated tools, educational content, equipment listings, and expert insights to support your work. Our goal is to help professionals stay informed, improve inspection quality, and connect with the best equipment and training available—no matter what industry you serve.

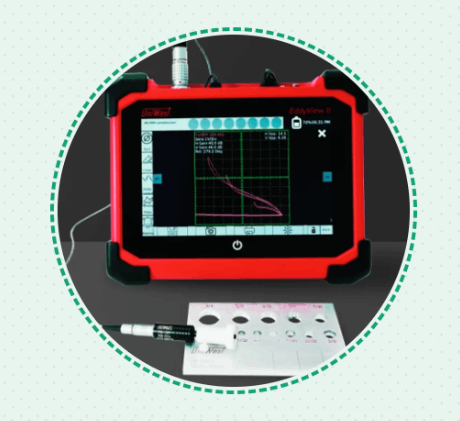

Ed's Latest Lab Video from EddyCurrentDOTcom YouTube Channel

ECT and NDT Library

Industry Applications

Global Energy Monitor

Energy News

Research Publications

Frequently Asked Questions

What is NDT?

Nondestructive testing (NDT) is the process of testing or inspecting a material, component, or system without causing damage to the test subject. There are several varieties of nondestructive testing, including traditional ultrasonic flaw detection, phased array testing, and eddy current testing.

NDT includes a wide group of analysis techniques used in science and industry to evaluate the properties of a material, component or system without causing damage.

• Other terms commonly used the describe NDT are: Non-destructive examination (NDE) Non-destructive inspection (NDI) Non-destructive evaluation (NDE)

NDT does not permanently alter the material being inspected.

• Time and cost effective as any problems can be rectified before becoming a terminal issue.

• NDT is used as a safety monitor in many industries including ensuring the planes and trains we travel on.

What are the benefits of nondestructive testing?

Nondestructive testing provides an abundance of advantages across a range of industries. Since NDT enables the tester to inspect materials such as metals, concrete, ceramics, plastics, and composites—even if only one side of the inspected part is accessible—it can be employed in both quality assurance and in-field testing of materials without needing to damage the test subject. NDT testing can be used to inspect pipes, bridges, dams, and other materials that require routine inspection.

What industries can eddy current apply to?

NDT is used in a variety of settings that covers a wide range of industrial activity.

• Automotive

• Aviation / Aerospace including Engines, Propellers, turbines, Outer Shell & Wheel Inspection.

• Power Plants

• Construction including Structures, Bridges

• Manufacturing

• Machine parts

• Castings and Forgings

• Industrial plants such as Nuclear, Petrochemical, Power, Refineries, Pulp and Paper, Fabrication shops, Mine processing.

• Pressure vessels

• Storage tanks

• Welds

• Boilers

• Heat exchangers

• Pipelines

• Leak Detection

• Rail

• Tubular NDT, for Tubing material

• Amusement park rides

• Submarines and other Naval warships

• Medical imaging applications.

What our clients says!

Our Latest News & Blogs