MAXWELL NDT is a newly founded company providing electromagnetic inspection technology. The vision is to bring together expertise in electromagnetic non-destructive testing, starting with Pulsed Eddy Current Technology (PECT).

PECT has been developed to detect corrosion hidden under insulation. Previous instruments often lacked the power to be fast and effective. Using the latest battery technology, MAXWELL NDT introduces a novel and very powerful PECT instrument. Its design is based on 20 years’ hands-on experience.

PECT Instrument

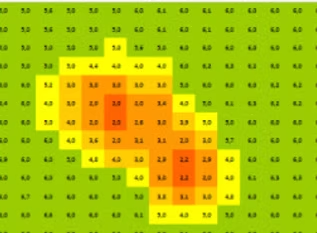

PECT Color-Coded Maps

Color-coded wall thickness readings are displayed on the touch screen display during data recording.

A MS-Excel field report can be produced quickly by the tablet computer. In addition, PC-based software is provided for further analysis and reporting.

PECT Probes

There are four standard probes, each for a different lift-off range. The probes are optimized for defect sensitivity.

The instrument can either be operated from the probe and from the tablet computer.

Introducing The Maxwell PECT II Pulsed Eddy Current System

The ideal screening tool for measuring wall thickness of pipes without having to remove the lagging, coating, deposits or marine growth. #NDT #PEC #PECT #Maxwell #FAC #Corrosion #insulation #CUI #Inspection #PipeWrap #AnnularRings #Offshore #MarineGrowth #SpashZone

Maxwell NDT Pulsed Eddy Current PECT System

Dare to compare the new Maxwell NDT PECT System for inspection of inaccessible corrosion. Developed after 30 years of oil industry experience.

From an original work by Paul Crouzen.

Script by Pete Burrows

Starring Pete Burrows

Narrated by Pete Burrows

Filmed, Directed and Produced John Hansen

Maxwell PECT Quick Start Guide

How to get up and running with the Maxwell Pulsed Eddy Current System