The VeeScan is ETher’s first Wheel Inspection System and offers maximum flexibility for the operating inspection environment.

SigmaCheck 2

The SigmaCheck 2 Eddy Current (ECT) Conductivity Meter is designed to provide the user with fast and accurate conductivity measurements at a reasonable price; whilst being extremely easy to use making it suitable for use by shop inspectors or engineers.

SteelCheck

SteelCheck is a dedicated single method tube inspection instrument for the identification of OD, ID Defects and Wall Thinning.

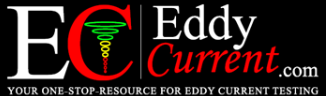

ACE-ACMFT

ViCTor 2.2D

ETher NDE introduces the ViCTor 2.2D, the user-friendly automated eddy current inspection system, designed with the Automation Engineer in mind. Based on our long standing range of core flaw detectors and software, NDT Inspectors will become quickly familiar with its user interface and with a variety of case configurations available, the ViCTor 2.2D offers maximum flexibility for each individual application.

ETi-300/350

ETi-200

The ETi-200 is an advanced Eddy Current Flaw Detector from ETher NDE. The ETi-200 is designed to offer advanced multi-frequency and multi-channel flaw detection housed in the smallest portable EC package on the market.

EmBed EC

EmBed EC is ideal for integrating Eddy Current into an automated system to provide a solution to varied applications.

AmCheck

Developed with the Additive Manufacturing industry in mind the AMCheck can be conveniently panel mounted for inspection of Additive Manufactured (AM) parts during inspection.

WeldCheck 3

The WeldCheck 3 is a dual-frequency eddy current flaw detector, with conductivity, which means that the instrument can be used for dual and single frequency applications.

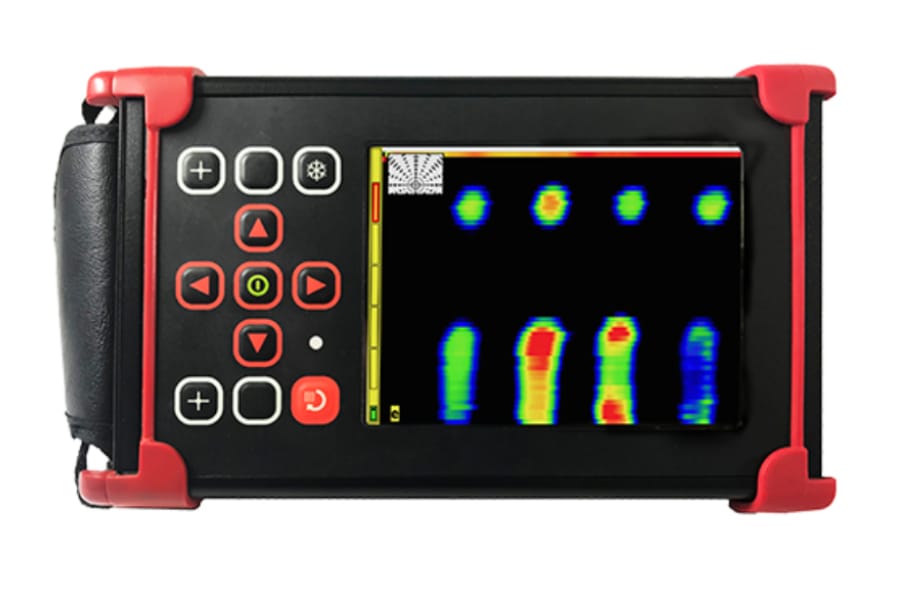

PhaseCheck

Introducing the latest addition to our core range, the PhaseCheck, an advanced dual probe, dual frequency advanced eddy current flaw detector with C-Scan capability.

EtherCheck

EtherCheck ET/Bond Testing Flaw Detector has been designed for NDE on Aerospace specific applications.

EtherCheck offers the operator a rich range of features combined with the most widely used acoustic bond testing method; Pitch-Catch. A common user interface between the two modes, resulting in simple operator led set up.

WeldCheck

The WeldCheck Series of Flaw Detectors appeals to users across a wide range of sectors including Offshore, Rope Access, Infrastructure NDT applications, plus other weld inspection requirements replacing MPI and LPI, especially on coated welds.